Ulaha Carbide Adag

![]() Hordhaca Ulaha Carbide Adag

Hordhaca Ulaha Carbide Adag

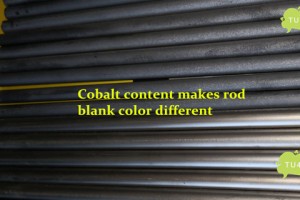

Usha carbide-ka adag waxaa inta badan laga sameeyaa carbide tungsten, cobalt biraha xira iyo qaar ka mid ah maaddooyinka kale ee shaqaynaya oo lagu daray sida qaacidadu u baahan tahay, iyada oo loo marayo isku-darka walxaha, soo-saaridda, ka-hor-dhumucda, habka wax-ka-beddelka qaab-dhismeedka ka dibna ku qulqulaya cadaadis hoose. Iyada oo leh astaamo adag, xoog sare, kiimiko deggan, isku -dheelitir ballaarinta hooseysa, korantada iyo kuleylka, ulaha carbide tungsten ee sintered ayaa si weyn loogu adeegsadaa aagga wax soo saarka warshadaha, tusaale ahaan, si loo sameeyo qoditaanka micro ee warshadaha PCB, baararka korontada ee bulshada indhaha warshadaha, qodista, kaydinta qodista, caarada, riixista, xiro qaybo sax ah oo iska caabiya, CNC reamer iyo baalal leh dalool qabow oo ku jira warshadaha farsamaynta.

Sida bakhaarka carbide, warshadda warshadda biraha ee Toonney tungsten waxay soo saartaa tiro badan oo daawaha tungsten ah oo ay ku jiraan ulaha adag, ulaha leh godka qaboojiyaha toosan/muquuninta, ulaha qaabeeya sida baahida macmiilka iyo T qaabeeya iwm.

Ulaha carbide tungsten ee adag, ma jiraan marinnada qaboojiyaha gudaha. Waxaan leenahay 10 shey oo caano ah oo loogu talagalay isticmaalka ugu badan, tusaale ahaan, ulaha loogu talagalay daloolka yar ee PCB, mashiinka wax lagu jaro, qori carbide, layliyada lagu farsameeyo daawaha aluminium, daawaha saldhigga naxaasta ah, daawaha saldhigga birta ah iyo; wolfram carbide iwm Waxaan si adag u xakamaynnaa tayada tallaabo kasta oo lagama maarmaan ah, waxaan dhihi karnaa tayada wanaagsan waa mid ka mid ah faa'iidooyinka taas oo naga dhigaysa inaan ka dhex istaagno warshadan.

Wolfram carbide: Wolfram carbide waa isku -dar ka kooban wolfram iyo carbide. Waa crystal hexagonal madow oo leh dhalaal macdan ah, kaas oo adkaysigiisu la mid yahay dheemanka.Wolfram carbide waa kaari wanaagsan oo koronto iyo kuleyl ah, kuma milmi karo biyaha, aashitada hydrochloric ama sulfuric acid, laakiin si fudud ayaa loogu milmi karaa xal isku dhafan ee nitric acid iyo hydrofluoric acid. Carbide saafi ah oo wolfram waa jilicsan yahay, laakiin ku dar titanium ama cobalt iyo sintered, qallafsanaantu aad bay u sarraysaa. Wolfram carbide waxaa sidoo kale loo yaqaannaa tungsten carbide.

Birta Tungsten/Tungsten macdan:Tungsten waxaa sidoo kale loo yaqaan wolfram, qaabka ugu badan ee biraha tungsten ee codsiga warshadaha waa tungsten carbide. Warshadda biraha ee Toonney tungsten waxay soo saartay ulaha carbide -ka adag sanado badan waxayna sumcad wanaagsan ku leedahay gudaha iyo dibaddaba.

Faahfaahinta Baakadaha: Bacda caaga ah, ka dibna lagu ilaaliyo xumbada, ugu dambayntii kartoon dibadda ah.

Muunadaha Muhiimka ah:Ulaha carbide -ga ee adag oo laga heli karo alaabadayada caadiga ah ee caadiga ah, waxaa lagu bixin karaa shaybaarro bilaash ah. Ulaha carbide -ka adag oo leh macmiil aan joogto ahayn ayaa loo baahan yahay, waa la qaadi doonaa. Dabcan, macaamiishu waxay u baahan yihiin inay bixiyaan khidmadda dhoofinta. Caadi ahaan, waqtiga hogaaminta ee shaybaarku wuxuu ahaan doonaa 7 maalmood oo shaqo gudahood.

Tirada Dalabka Ugu Yar: Ma jiro tiro dalabka ugu yar oo ah ulaha carbide adag ee amarka tijaabada koowaad. Laakiin amarka labaad, wadarta guud ee usha carbide -ka adag waa inaysan ka yarayn 1000 USD.

Waqtiga dirida: 7-15 maalmood oo shaqo

![]() Qalabka Jarista Jadwalka Fasalka iyo Codsiga

Qalabka Jarista Jadwalka Fasalka iyo Codsiga

| Darajo | Co % | Badarka Siz (μm) | Cufnaanta (g/cm3) | Engegnaantiinna (HRA) | TRS (N/mm2) |

| TU90 | 9.0 | 0.2 | 14.35 | 94.1 | 5200 |

| TF06 | 6.0 | 0.6 | 14.81 | 93.1 | 4000 |

| TU06 | 6.0 | 0.4 | 14.8 | 94.3 | 4600 |

| TU08 | 8.0 | 0.4 | 14.52 | 93.5 | 4800 |

| TU08S | 8.0 | 0.3 | 14.5 | 93.6 | 5000 |

| TU40 | 10.0 | 0.8 | 14.4 | 91.7 | 4600 |

| TU40F | 10.0 | 0.6 | 14.45 | 92.3 | 4600 |

| TU40S | 10.0 | 0.5 | 14.5 | 92.5 | 4800 |

| TU44 | 12.0 | 0.4 | 14.1 | 92.6 | 4800 |

| TU25 | 12.0 | 0.6 | 14.06 | 92.5 | 4200 |

| TU45 | 13.0 | 0.3 | 13.95 | 92.7 | 4800 |

| TU55 | 13.0 | 0.3 | 13.92 | 92.6 | 4800 |

![]() Codsiga Lagu Taliyay

Codsiga Lagu Taliyay

| Darajo | Codsiga lagu taliyay |

| TU90 | Qalabka wax lagu jaro oo lagu farsameeyo walxo la bakhtiiyay (HRC65-70), alwaax adag iyo jarayayaal sare oo wax lagu qurxiyo. Aad bay ugu fiican yihiin kuwa wax jaraya oo dhammaynaya mashiinnada 316L birta aan bilaa macnaha ahayn |

| TF06 | Qalabaynta goynta mashiinka aluminium aluminium aluminium, garaaf iyo fiber isku jira. |

| TU06 | Waayo, PCB micro-daloolin iyo dhammaad mishiinka biraha suunka sare sare. |

| TU08 | Waayo, PCB micro-daloolin, mini-magaabay wiil. |

| TU08S | Daloolinta PCB-ga micro-ga, aaladaha goynta loogu talagalay makiinadaha la damiyay finanka (HRC60-65), 316L birta birta ah, xaashida biraha ee aad u saraysa iyo xaashida birta silikon. |

| TU40 | Wixii qoditaan qodis ah ee caadiga ah, dhammaadka dhagaxshiidka iyo feerku waa dhintaan. |

| TU40F | Wixii xoogaa qoditaan ah, dhammaadka dhagaxa mashiinka mashiinka dhejiska, birta aan birta lahayn iyo birta kabka ah. |

| TU40S | Qalabaynta goynta mashiinnada 316L birta birta ah, walxaha ugu fiican ee loogu talagalay cuctters -ka caadiga ah. |

| TU44 | Qalabka jarista mashiinka dhagaxa titanium, kuleylka u adkaysta, birta aan birta lahayn, birta quustay (HRC55 iyo wixii ka sareeya), birta kabka cawlan. |

| TU25 | Qalabka wax lagu jaro oo lagu farsameeyo kulaylka birta lagu daweeyo (Hardness HRC45 iyo ka kor), birta birta ah, birta birta ah. |

| TU45 | Qalabka jarista titanium mashiinka, kuleylka u adkaysta, birta aan birta lahayn, birta quusnched (HRC60 iyo kor) |

| TU55 | Darajo leh guduud-adayg aad u sarreeya, oo u fiican jarista aaladaha makiinadda heerkulka sare ee daawaha u adkaysta, birta la demiyey (HRC60 iyo wixii ka sarreeya) iyo daawaha titanium |

![]() Faahfaahinta Ulaha Carbide Adag

Faahfaahinta Ulaha Carbide Adag

| Di. Ø mm |

Dulqaad. (Mm) | Dhererka (mm) | Tol. (Mm) | Dia.Ø (mm) | Dulqaad. (Mm) | Dhererka (mm) | Tol. (Mm) |

| 2.0 | +0.30/+0.15 | 330 | 1.5 | 16.5 | +0.8/+0.3 | 330 | 1.5 |

| 2.5 | +0.30/+0.15 | 330 | 1.5 | 17.0 | +0.8/+0.3 | 330 | 1.5 |

| 3.0 | +0.50/+0.30 | 330 | 1.5 | 17.5 | +0.8/+0.3 | 330 | 1.5 |

| 3.5 | +0.50/+0.30 | 330 | 1.5 | 18.0 | +0.8/+0.3 | 330 | 1.5 |

| 4.0 | +0.50/+0.30 | 330 | 1.5 | 18.5 | +0.8/+0.3 | 330 | 1.5 |

| 4.5 | +0.50/+0.30 | 330 | 1.5 | 19.0 | +0.8/+0.3 | 330 | 1.5 |

| 5.0 | +0.50/+0.30 | 330 | 1.5 | 19.5 | +0.8/+0.3 | 330 | 1.5 |

| 5.5 | +0.50/+0.30 | 330 | 1.5 | 20.0 | +0.8/+0.3 | 330 | 1.5 |

| 6.0 | +0.50/+0.30 | 330 | 1.5 | 20.5 | +0.8/+0.3 | 330 | 1.5 |

| 6.5 | +0.50/+0.30 | 330 | 1.5 | 21.0 | +0.8/+0.3 | 330 | 1.5 |

| 7.0 | +0.50/+0.30 | 330 | 1.5 | 21.5 | +0.8/+0.3 | 330 | 1.5 |

| 7.5 | +0.50/+0.30 | 330 | 1.5 | 22.0 | +0.8/+0.3 | 330 | 1.5 |

| 8.0 | +0.50/+0.30 | 330 | 1.5 | 22.5 | +0.8/+0.3 | 330 | 1.5 |

| 8.5 | +0.50/+0.30 | 330 | 1.5 | 23.0 | +0.8/+0.3 | 330 | 1.5 |

| 9.0 | +0.60/+0.30 | 330 | 1.5 | 23.5 | +0.8/+0.3 | 330 | 1.5 |

| 9.5 | +0.60/+0.30 | 330 | 1.5 | 24.0 | +0.8/+0.3 | 330 | 1.5 |

| 10.0 | +0.60/+0.30 | 330 | 1.5 | 24.5 | +0.8/+0.3 | 330 | 1.5 |

| 10.5 | +0.60/+0.30 | 330 | 1.5 | 25.0 | +0.8/+0.3 | 330 | 1.5 |

| 11.0 | +0.60/+0.30 | 330 | 1.5 | 25.5 | +0.8/+0.3 | 330 | 1.5 |

| 11.5 | +0.60/+0.30 | 330 | 1.5 | 26.0 | +0.8/+0.3 | 330 | 1.5 |

| 12.0 | +0.60/+0.30 | 330 | 1.5 | 26.5 | +0.8/+0.3 | 330 | 1.5 |

| 12.5 | +0.60/+0.30 | 330 | 1.5 | 27.0 | +0.8/+0.3 | 330 | 1.5 |

| 13.0 | +0.60/+0.30 | 330 | 1.5 | 27.5 | +0.8/+0.3 | 330 | 1.5 |

| 13.5 | +0.60/+0.30 | 330 | 1.5 | 28.0 | +0.8/+0.3 | 330 | 1.5 |

| 14.0 | +0.70/+0.30 | 330 | 1.5 | 28.5 | +0.8/+0.3 | 330 | 1.5 |

| 14.5 | +0.70/+0.30 | 330 | 1.5 | 29.0 | +0.8/+0.3 | 330 | 1.5 |